Stability and Continuity

ROUNDO was formed in 1964, and has since delivered almost 16 000

machines to satisfied customers around the globe. The company is

still in the hands of its original owners. This has provided a

stability and continuity that is unique in our industry. ROUNDO

is currently represented throughout the world. ROUNDO machines

are world-renowned for outstanding performance,

reliability and quality.

Dedication and

Know-how

ROUNDO has a team of over 75 dedicated full-time employees. They

are capable of shipping over 300 machines per year, of which 97%

are exported around the world. ROUNDO engineers and technicians

employ cutting-edge technologies and renowned Swedish technical

skills and know-how. The result is products that represent

quality, performance and reliability unique on the global

market.

|

|

Main Plant - 65,000 Sq. Ft.

Office space with design, sales,

marketing, financial and purchase departments and state

of the art workshop. ROUNDO has full control over all

parts of the production process, from welding and

machining to assembly. |

Welding shop - 45,000 Sq. Ft.

Close to the main plant ROUNDO has their

own welding shop where all welding as well as the

extremely heavy mechanical work is performed. ROUNDO

machines are built from the ground up. |

Angle Bending Rolls Angle Bending Rolls

ROUNDO offers the largest

selection of angle and section bending machines on the market with over 25 different standard sizes, from the R-1,

the smallest

machine, to the R-21-S, the strongest section bending machine

in the world! The machines are always more powerful and more

heavily proportioned in terms of frame, shaft size, bearings and

drive torque than machines from other suppliers. CNC controls

and a wide array of options are available for all models.

ROUNDO ROLLS OVER THE COMPETITION BY FEATURING:

-

Heaviest

Proportioned Frame - for added strength and rigidity

-

Largest

Diameter Roll Shafts - to minimize deflection, improving results

-

Largest Roll

Shaft Bearings - for greatest efficiency and long life

-

Highest Drive

Torque - means fewer passes and less deformation

-

Greatest

Bending Roll Force - generated by the rolls, providing

the largest section modulus capacity

-

Most Powerful

Guide Rolls - to efficiently take the twist out of the

heaviest sections

|

|

TWO BROAD RANGES OF ROUNDO

ANGLE ROLLS:

R-1 to R-6 are basic machines

for all types of section bending. The guide rolls are

manually adjusted and fixed to the swing arms.

R-2-S to R-21-S offer enhanced

versatility due to the unique design of the multi-directional

hydraulic guide rolls and increased capacity. |

MAIN ADVANTAGES WITH ROUNDO BENDING MACHINES

The main frame on all ROUNDO bending machines is welded steel construction, machined

and line bored using the heaviest components of any comparable

machine for added strength and rigidity. ROUNDO is the only

manufacturer who stress-relieves every frame after welding.

ROUNDO roll shafts are made from high-strength chrome-nickel alloy

steel, and are the largest diameter shafts of any comparable

machine. These heavily proportioned shafts help minimize

deflection, resulting in improved bending. The roll shafts are journalled in oversized SKF roller bearings for greatest

efficiency and long life. The standard tooling is a combination

set for bending angles both leg-out and leg-in, flat bar on flat

and on edge, T-bar stem-out and stem-in as well as stem-down,

small square bar and even small solid round bar. Normally, no

additional spacers are required.

ROUNDO angle bending

machines provide the greatest drive torque of any comparable

machine. Greater drive torque means the section can

generally be rolled in fewer passes, often resulting in less

deformation to the section being rolled. All three rolls are

driven at all times. The rotation speed on all models is

generally 23 feet/min, considerably faster than other comparable

machines, and high speed packages are also available!

The two lower rolls are individually adjusted by hydraulic

cylinders. The rolls are sized to allow ROUNDO angle

bending rolls to generate more bending power than any

comparable machine, providing the largest section modulus

capacity.

ROUNDO angle bending

machines feature the largest, most powerful guide rolls

available on the market. This allows them to take the twist out

of the most massive sections within the capacity of the machine.

The hardened steel guide rolls, including "leg-in" guide rolls,

are standard on every model. 4-directional hydraulically powered Guide Rolls are standard

on Models R2S to R4S and 6-directional hydraulically powered

Guide Rolls are standard with Models R5S and larger.

ROUNDO machines can be found all

across the world including over 4000 in North America alone. Our

featured customers include a large percentage of Fortune 500

companies: Click for References.

|

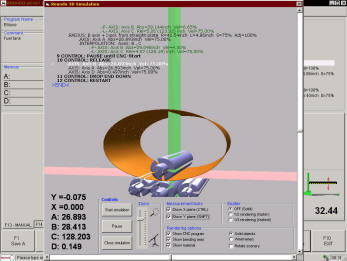

The First with a CNC System

In 1985, ROUNDO was the first to develop CNC controls specifically

adapted to bending machines. Since then, we have

steadily enhanced and expanded the capabilities of our

systems, allowing us to maintain our position as the

world leader in this area as well.

|

"The ROUNDO CNC control system can position the rolls to

within ± 0.004”, even under varying loads. These tight

tolerances are unmatched by any competitive machine." |

ROUNDO CNC Circa 1985 |

| Unlimited Capacity

The ROUNDO control systems

have practically unlimited capacity regarding the number

of programs and the size of each program. The computer

in the CNC system can be connected to the customer’s

network, providing a simple means of data backup. The

software can also be installed in an office PC, allowing

finished bending programs to be created in advance. This

allows the machine to be available for production for a

longer period of time.

The ROUNDO wCNC² Control is

a PC-based CNC control running under Microsoft® XP,

providing an operator-friendly graphical interface. This

highly advanced and powerful system can control up to 24

axes, including the main bending rolls, and any type of

optional equipment. Also communication with peripheral

units such as industrial robots or material handling

systems is easily integrated in our unique system. The ROUNDO wCNC² Control is

a PC-based CNC control running under Microsoft® XP,

providing an operator-friendly graphical interface. This

highly advanced and powerful system can control up to 24

axes, including the main bending rolls, and any type of

optional equipment. Also communication with peripheral

units such as industrial robots or material handling

systems is easily integrated in our unique system.

Always One Step Ahead

The ROUNDO wCNC² Control

software includes a library of bending wizards to

rapidly produce good parts. Even short runs can be

efficiently rolled using this system. The CNC Control is

available for all models.

|

The ROUNDO RLC/3 Logic

Control System is a PLC based control system designed

and developed normally for small section and plate

bending machines. This system can control up to 7-axes

and the possibility to use USB memory allows infinite

number of bending programs.

The ROUNDO RLC/1 Position

Control System is a basic positioning control with

possibility to preset two values for each axis. The

positioning control automatically stops the movement of

the bending roll when the pre-set value is reached. The

system is designed to make repetitive bends.

|

A few important questions to which you

should demand answers before purchasing a plate or

angle bending machine:

-Are there references from satisfied customers

concerning service, life and quality? There are

over 4000 ROUNDO Bending Rolls in North America. Trilogy

Machinery handles the parts, service and support for

each one of them. We will gladly provide you with an

extensive list of customers in your area for reference.

-Will the machine meet your present as well as your

future needs? Not only will the ROUNDO roll out

last the competition but most can be upgraded with the

latest CNC controls and equipment.

-To what extent is technical expertise, support and

service provided? If their answer is "We can ask

the factory", that should be an immediate indication to

look elsewhere. The staff at Trilogy have more

direct/hands-on experience than any other distributor in

North America.

-What is the cost of the machine distributed over its

expected service life? While many competitors

claim to save you money initially, over time the expense

to maintain their machines may be drastic. ROUNDO is the

most popular bending machine on the used market solely

because of its PROVEN long service life. |

|